In optical measuring systems, magnification is often misunderstood as simply “making the image look bigger.” In practice, whether it is a Video Measuring Machine or a visual measuring system, the key factor affecting measurement results is how the optical system maps the physical geometry of a workpiece onto the image sensor for sampling, not the display size. A video measuring machine or any optical measuring device derives measurement capability from proper imaging and sampling conditions, rather than visual appearance. Even if the image is digitally zoomed on the display, measurement uncertainty will not improve if the optical sampling conditions are insufficient. High-end VMMs are therefore designed with optical magnification as a core parameter.

Optical Magnification Increases Spatial Sampling Density

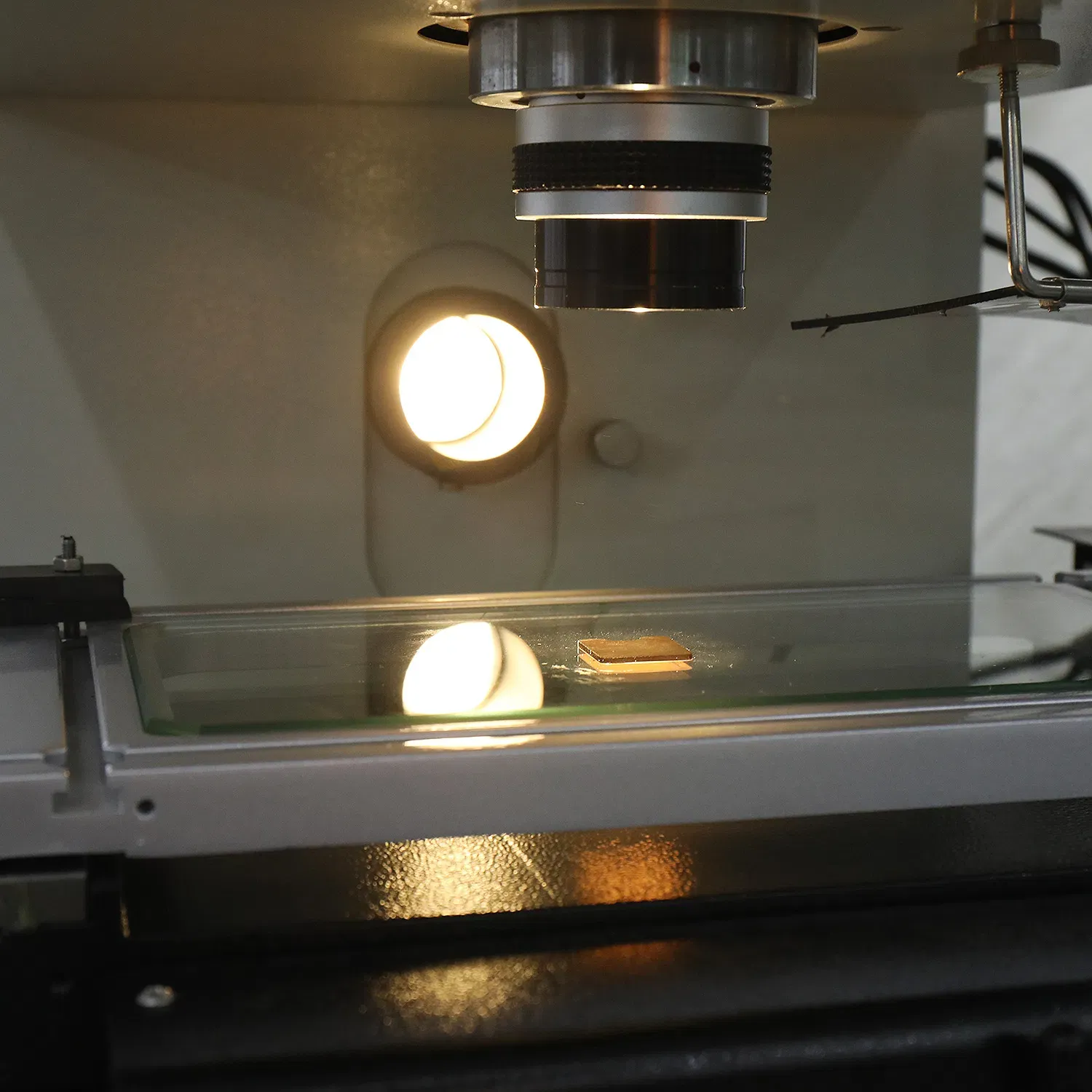

In any optical measurement system, the pixel size of the image sensor is fixed. Optical magnification changes the ratio between pixel and actual workpiece size. When magnification is increased, the same physical length covers more pixels on the imaging plane, reducing the physical size represented by each pixel. The workpiece edge is sampled more densely, giving the system higher spatial sampling density at the object side. In both visual measurement machines and video measuring machines, this denser sampling reduces discretization errors in dimension data, directly lowering measurement uncertainty.

Pixel Quantization Uncertainty Is Compressed

Pixel quantization is an unavoidable source of uncertainty in image-based measurement. At low optical magnification, an edge may span only a few pixels, and the measured edge position is highly sensitive to individual pixel states. Small changes in lighting, focus, or sensor noise can significantly affect measurement results. Increasing optical magnification allows edges to span more pixels, decreasing the influence of any single pixel and improving repeatability and stability. This principle is why magnification is carefully considered in VMM design.

Edge Sampling Improves Measurement Stability

Workpiece edges are rarely ideal lines; they usually appear as grayscale transitions in images. Optical magnification allows these transitions to be sampled by more pixels, providing sufficient data for precise edge detection. In video measuring machines and visual measuring systems used for small stamping parts, precision plastics, or electronic components, this improved sampling significantly enhances the consistency of repeated measurements. Engineering experience shows that adequate optical sampling conditions often contribute more to measurement stability than complex software algorithms.

Subpixel Measurement Relies on Optical Foundation

Subpixel measurement is not a way to bypass pixel limitations; it estimates edge positions based on multiple pixels’ grayscale distribution. Optical magnification increases the number of pixels per unit length, making grayscale transitions more continuous and improving subpixel reliability. If magnification is insufficient, even the most sophisticated algorithms cannot significantly reduce measurement uncertainty. Digital magnification only enlarges the displayed image, without adding effective sampling points, and therefore does not impact measurement accuracy in visual measuring machines or VMMs.

From an engineering perspective, the value of optical magnification lies in physically increasing spatial sampling density, improving dimensional information acquisition at the object level. This is why optical magnification is indispensable in controlling measurement uncertainty, something digital zoom or post-processing alone cannot achieve. In high-end video measuring machines and visual measuring systems, optical magnification, sampling density, and subpixel processing work together to determine overall measurement precision and stability.

For more information, please click on the link below.

https://www.jatentech.com/blog/video-measuring-machine-mechanical-structure-long-term-stability

https://www.jatentech.com/blog/multi-angle-illumination-optical-measuring-machines